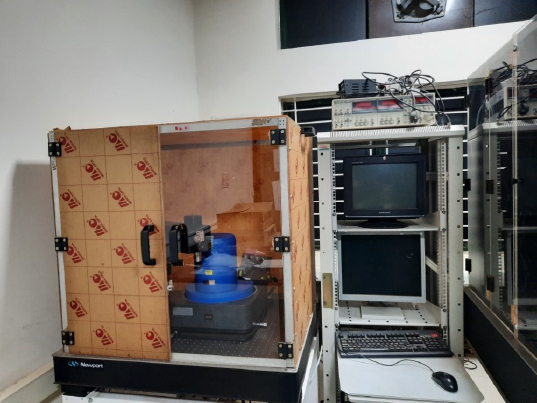

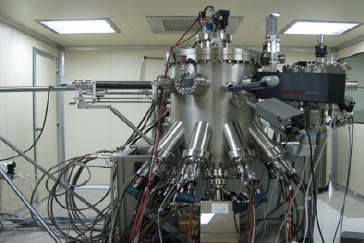

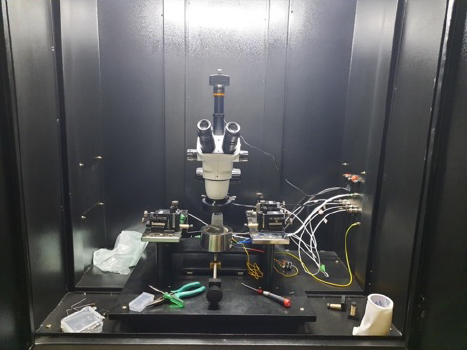

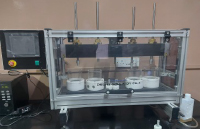

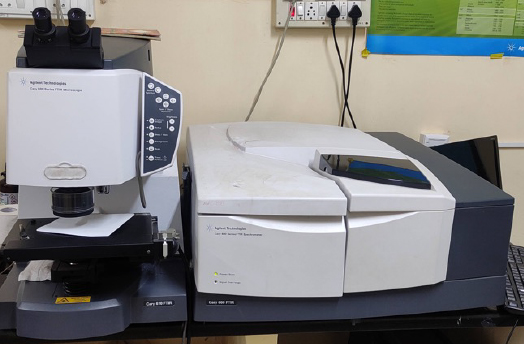

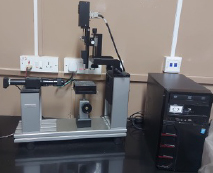

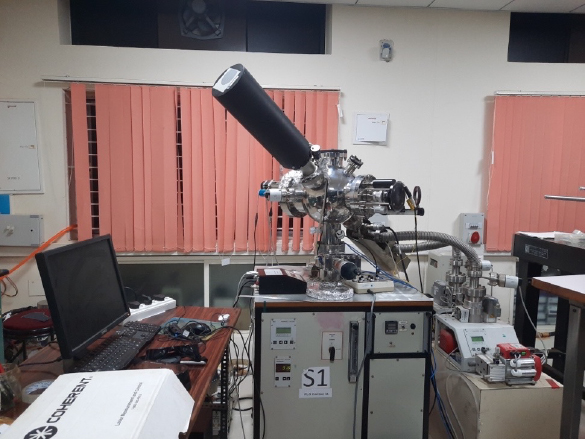

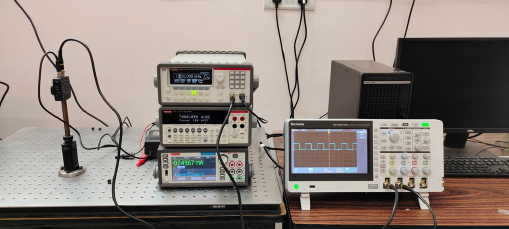

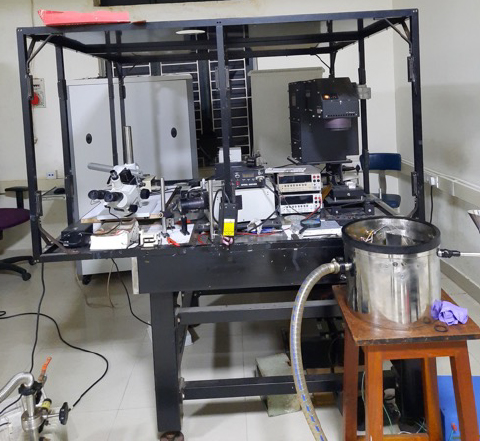

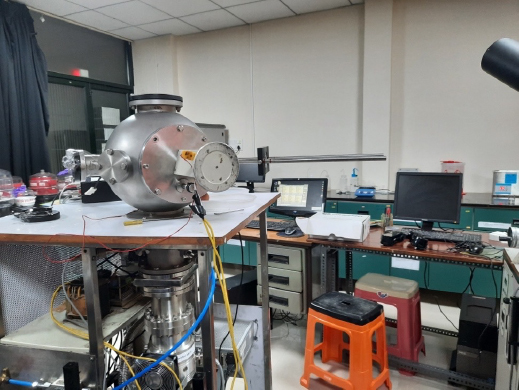

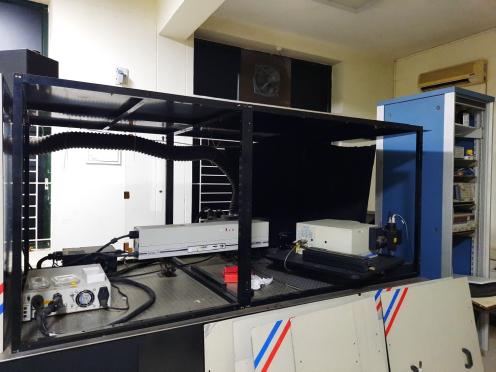

Facilities

The Materials Research Center is well served with equipment for processing and characterization of the materials. The equipment listed could either be central facilities (marked CF) or associated with the laboratories of individual faculty members. {N. Ravishankar, Karuna Kar Nanda, Bikramjit Basu, Abhishek Singh, Balram Sahoo, Prabeer Barpanda, Subinoy Rana, Pachaiyappan Rajamalli, Sujit Das}. Apart from departmental facilities the students also have access to institute and national facilities such as the characterization facilities in the Institute Nano-Science Initiative.